TO CREATE A PO FILL RATE BY PO

The PO Fill Rate by PO is a key performance indicator (KPI) used in procurement, supply chain, and inventory management. It measures the percentage of a specific Purchase Order (PO) that has been fulfilled or “filled” in terms of quantity, typically delivered or stocked against what was originally ordered.

User Access

Who Can Access

- Pothys admin

- Back Office

- Purchase Manager

- Manager

What User Can Do

- View Reports

- PO Fill Rate By PO .

Pre-Requisite Activities

- PO Date

- Vendor

Business Rules

The formula for calculating the PO Fill Rate for a specific PO is:

If a company placed an order for 100 units of a product and the supplier delivered 90 units,

the PO Fill Rate would be:

PO Fill Rate=(90/100)×100=90%

- Quantity Ordered: The number of units or items requested in the purchase order.

- Quantity Delivered: The number of units or items actually delivered by the supplier.

Importance:

- Inventory Management: A low fill rate can indicate problems with stock management or supplier issues.

- Supplier Performance: A consistently low fill rate may signal that a supplier is unable to meet demand, which could necessitate finding alternate suppliers.

- Order Fulfillment: Helps businesses understand how well they are fulfilling customer orders based on the inventory delivered.

- Operational Efficiency: High fill rates typically indicate smoother operations and less disruption in the supply chain.

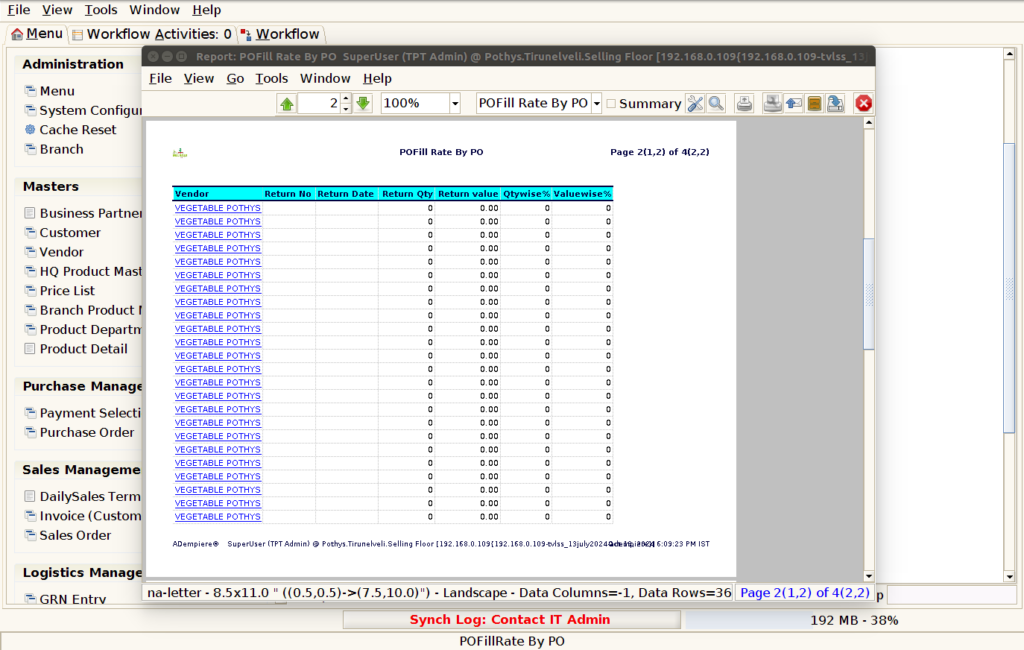

User Interface

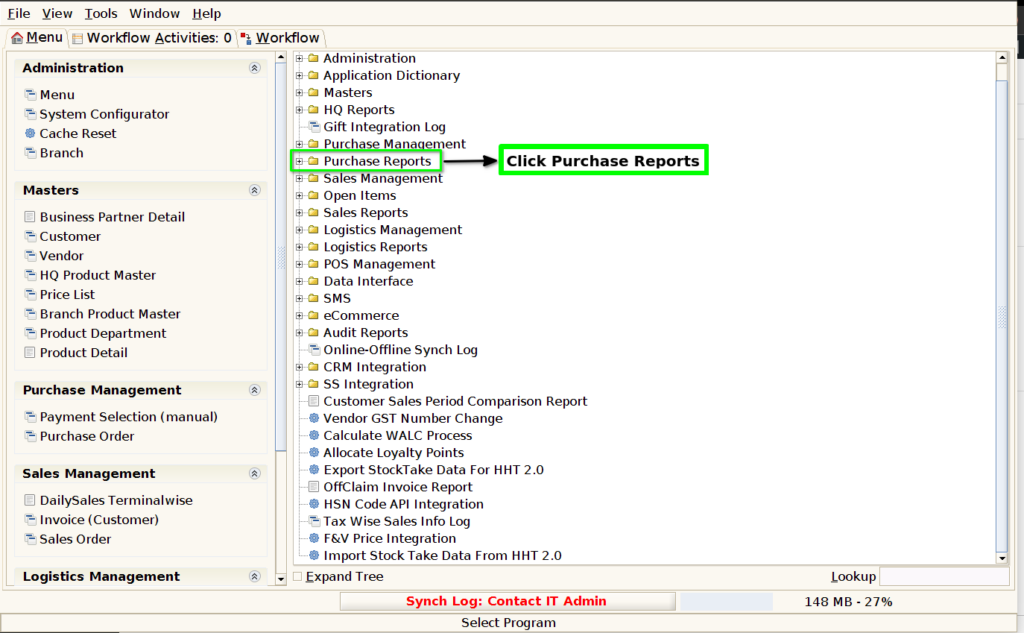

STEP1: Click Purchase Reports Folder.

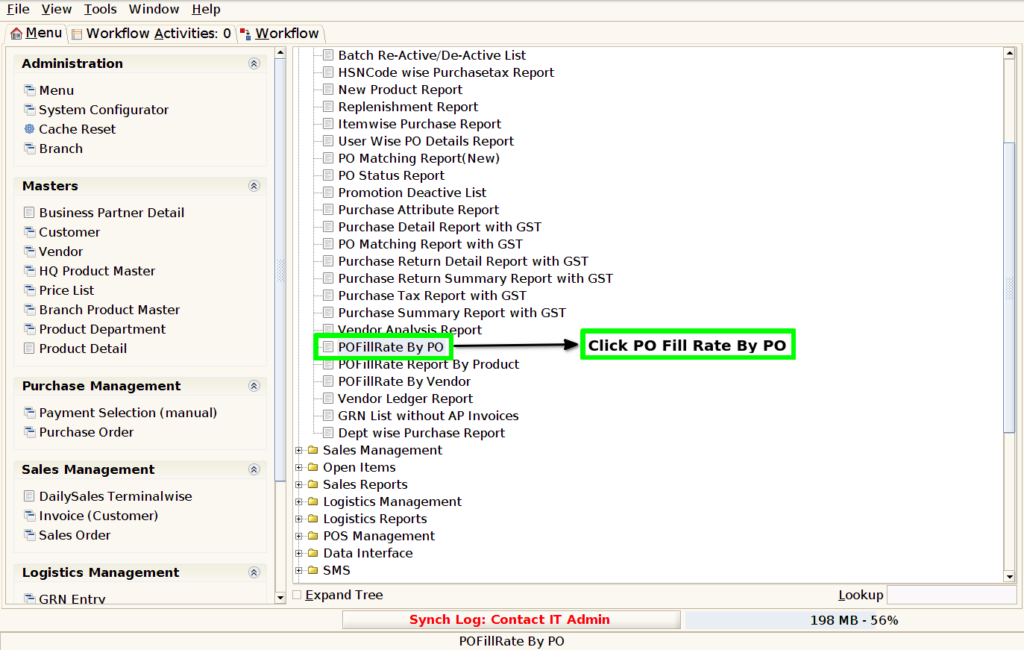

STEP2: Click PO Fill Rate By PO.

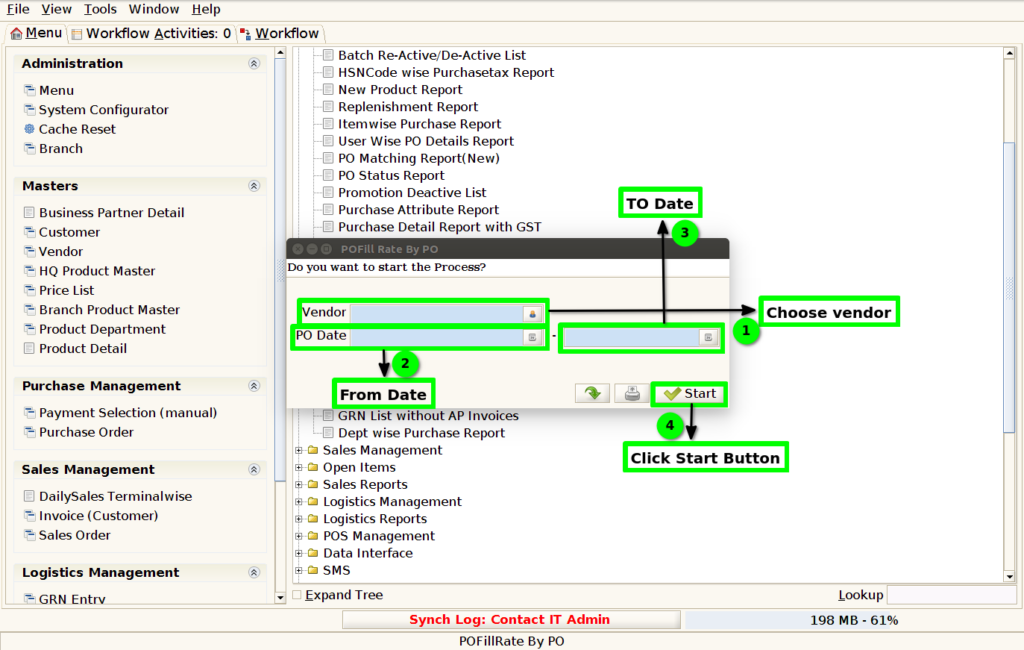

STEP3: Choose Parameter From Date, To Date and Vendor Mandatory.

STEP4: To show the report based on the given data.

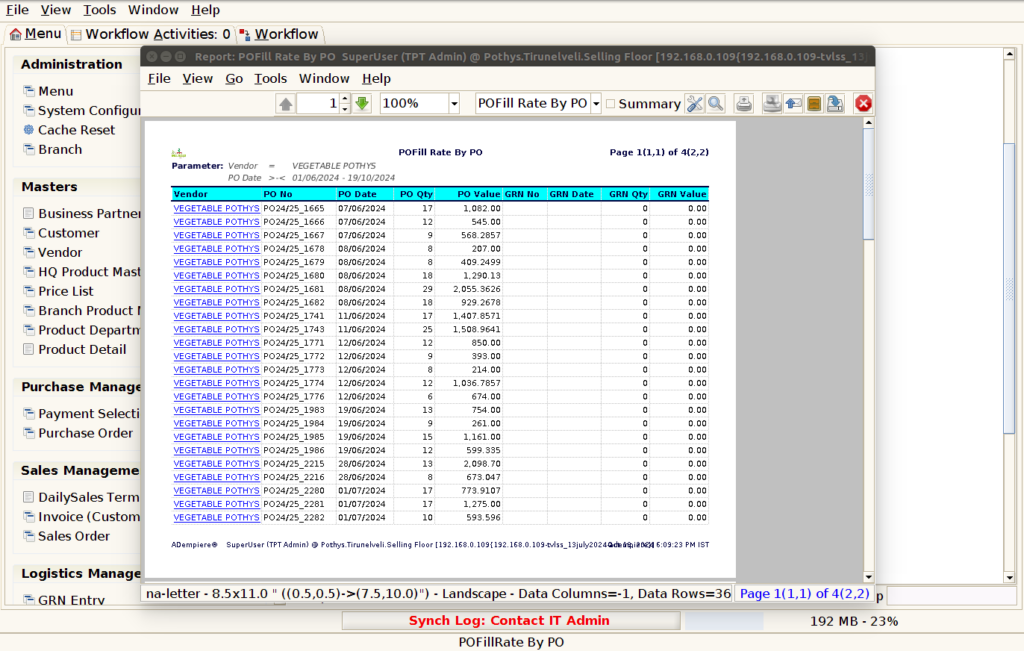

STEP5: Vendor Name-refers to the name of a company, individual, or organization that provides products, goods, or services to another business or consumer.

Purchase Order Number -A Purchase Order Number (PO Number) is a unique identifier assigned to a purchase order when it is created. It helps track and manage orders between buyers and suppliers.

Purchase Order Date-The Purchase Order Date is the date on which a purchase order (PO) is created or issued by the buyer. It serves as an official record of when the order was placed, and it’s important for tracking purposes, payment schedules, and delivery timelines.

Purchase Order Quantity-The purchase order quantity (PO quantity) refers to the amount of a product or material specified in a purchase order (PO) that a buyer requests from a supplier. It represents the number of units of goods or services that the buyer intends to acquire.

Purchase Order Value-The Purchase Order (PO) Value refers to the total monetary amount specified in a purchase order document. It represents the cost of the goods or services being ordered from a supplier. The PO value includes the unit prices of each item or service, the quantities being ordered, and any applicable taxes, shipping costs, discounts, or other adjustments.

GRN Document Number-The term GRN (Goods Receipt Note) Document Number typically refers to a unique identification number assigned to a goods receipt note in inventory or supply chain management. This number is used to track and reference the receipt of goods or materials from a supplier or vendor into a company’s inventory system.

GRN Date-The GRN date would refer to the date when goods are received and recorded into the inventory system.

GRN Quantity– GRN Quantity refers to the quantity of goods or items that are recorded on a Goods Receipt Note (GRN) when the goods are received from a supplier. The GRN is an important document used in inventory management and supply chain processes to confirm that the goods received match the order placed in terms of quantity, type, and condition.

GRN Value -refers to the total value of goods that have been received and logged into the system as part of a goods receipt process. It is essentially a record confirming that items have been received, and it typically includes information about the quantity, price, and type of goods delivered.

Return Document Number-A GRN (Goods Receipt Note) return document number refers to a specific identifier assigned to a return transaction related to goods that were previously received. The GRN is typically used in inventory and supply chain management to confirm the receipt of goods, and when goods are returned, a separate document number is often generated to track and manage that return.

Return Date-Purchase Order Returns: In a business-to-business (B2B) context, the vendor return date could refer to the last date a company can return unsold or defective inventory to the vendor.

Return Quantity-Retail & E-commerce: The return quantity refers to the number of items a customer returns after purchasing them. This could be due to reasons like defects, dissatisfaction with the product, wrong item received

Return Value-The GRN return value essentially represents the outcome or response after processing a GRN, whether it’s a success, error, inventory update, or other related results in the context of goods receipt and inventory management.

Quantity Wise %-Part Quantity is the specific amount you’re interested in (e.g., the number of items in a category).Total Quantity is the total amount or the sum of all quantities you’re comparing against (e.g., the total number of items).

Training Videos

FAQ

SOP