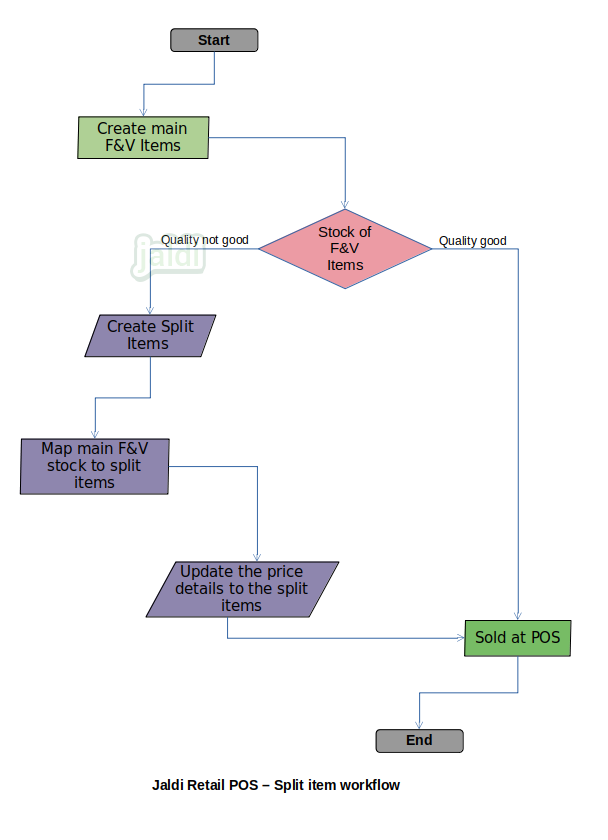

Split item process in Retail POS

Split items is the process which helps store to sale low quality products in less price to increase profit.

- This process mostly applicable only to fruits & vegetables items.

- The purpose of split item is used for splitting the item like onion 100 KG into three sub items depends on their quality like first grade,second grade and third grade onion in different prices to sale low quality items.

Split item creation

When the main item’s quality is reduced at store and customers are not purchasing those low quality products on their selling rate, User will now need to use the split process option to create the split item and set prices for the split items to sale those low quality items.

Business rules

- To create a split items user should go to item master screen and create split items same like other common F&V items. Ex – If main item is onion, create split items as onion 1, onion 2 & onion 3.

- Now User should move to split item mapping master screen which is under inventory master.

- User should load main item (Ex- Onion ), then system will show main items stock (Ex- onion – 100kg).

- Then user should load split items one by one and split the main items stock to the split items based on the quality of stock.

- After splitting the stock of main items to split items, save split item mapping master by pressing the “save” function key.

Price update for the Split items

Once the Split item creation and split item mapping is completed, user should update the selling and MRP price of the each split items for to sale the split items in POS sales screen.

Business rules

- User can find the split item screen and load the main item and it auto load the mapped split items with mapped stock.

- Then user will enter the price details for selling and MRP for each split items wise and save the details by pressing the function key “save”.

- Once all the details saved, in POS sales screen both main items and split items will be loaded with current stock and user can make sales using those stocks.

Split item process in retail POS workflow