TO CREATE A PO FILL RATE REPORT – PURCHASE REPORT

Purchase Order Fill Rate Report is a report commonly used in supply chain and inventory management to track how well suppliers fulfill purchase orders (POs). It measures the percentage of the total order quantity that is actually delivered compared to what was originally ordered.

User Access

Who Can Access

- Pothys admin

- Back Office

- Purchase Manager

- Manager

What User Can Do

- View Reports

- PO Fill Rate Report Purchase report

Pre-Requisite Activities

- Movement Date

- Purchase attribute

- Brand

- Product

- Product Department

- Item Type

- Vendor

Business Rules

- PO (Purchase Order) Fill Rate Report- is an important tool used in procurement and inventory management. It helps assess how well suppliers are fulfilling purchase orders and can be a key performance indicator (KPI) for vendor performance.

- Back ordered Items- If some items are back ordered, they should be excluded from the fill rate calculation for the current period.

- Expected Delivery Date for Back orders- The system should track the expected delivery date for back ordered items.

- Multiple Suppliers for One PO – If a PO is split between multiple suppliers, the fill rate should be calculated separately for each supplier.

- Time Period and Reporting Frequency – The fill rate should be calculated for each reporting period (e.g., daily, weekly, monthly).

- Item-Level Fill Rate- Track fill rates for individual items on the PO, as some items may be filled completely, while others may have partial deliveries.

User Interface

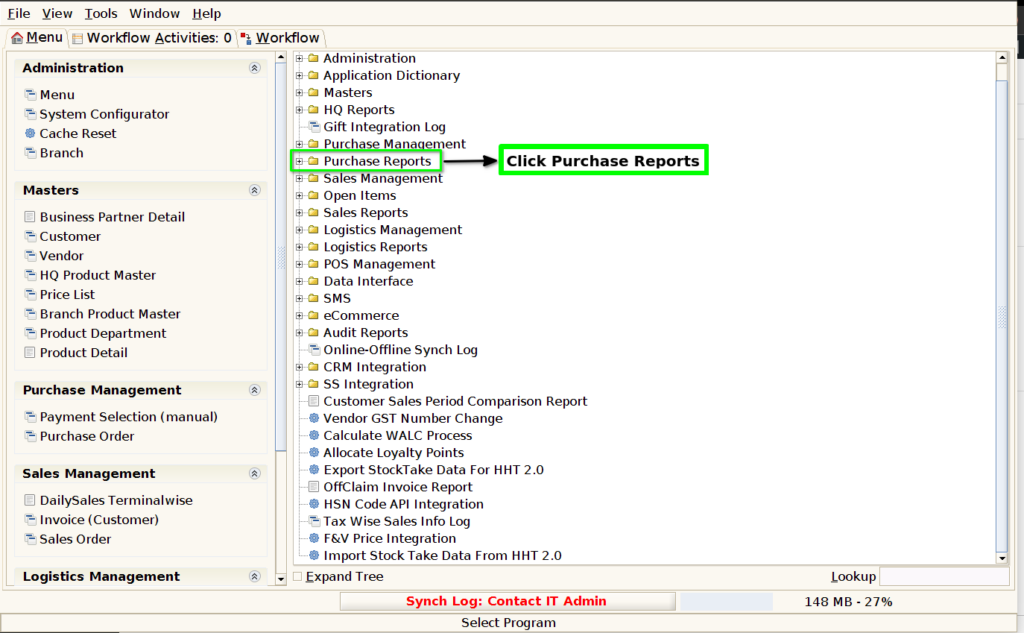

STEP1: Click purchase reports.

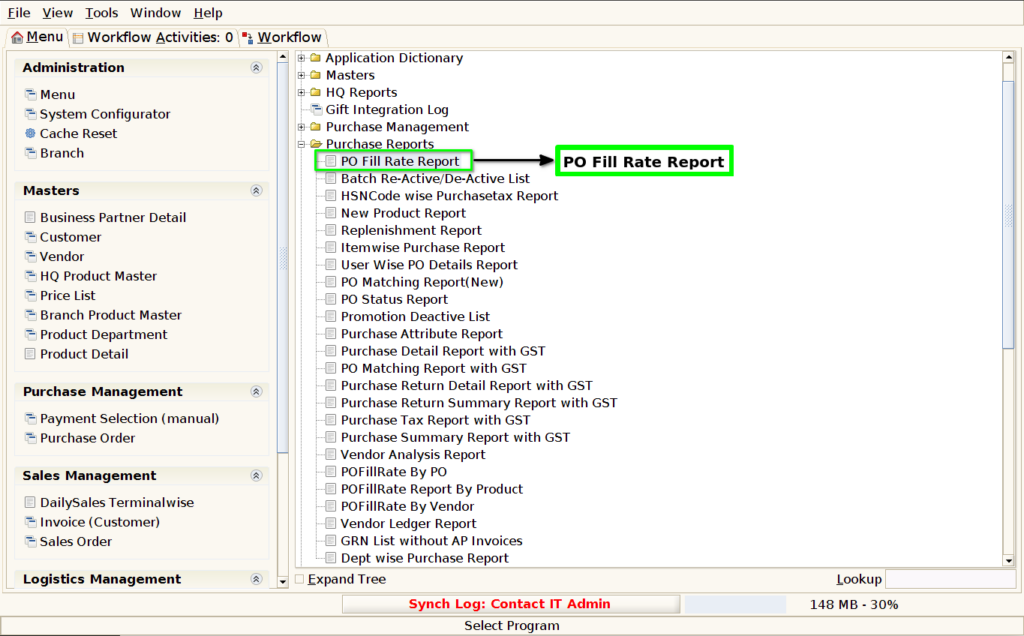

STEP2: Click PO Fill Rate Report.

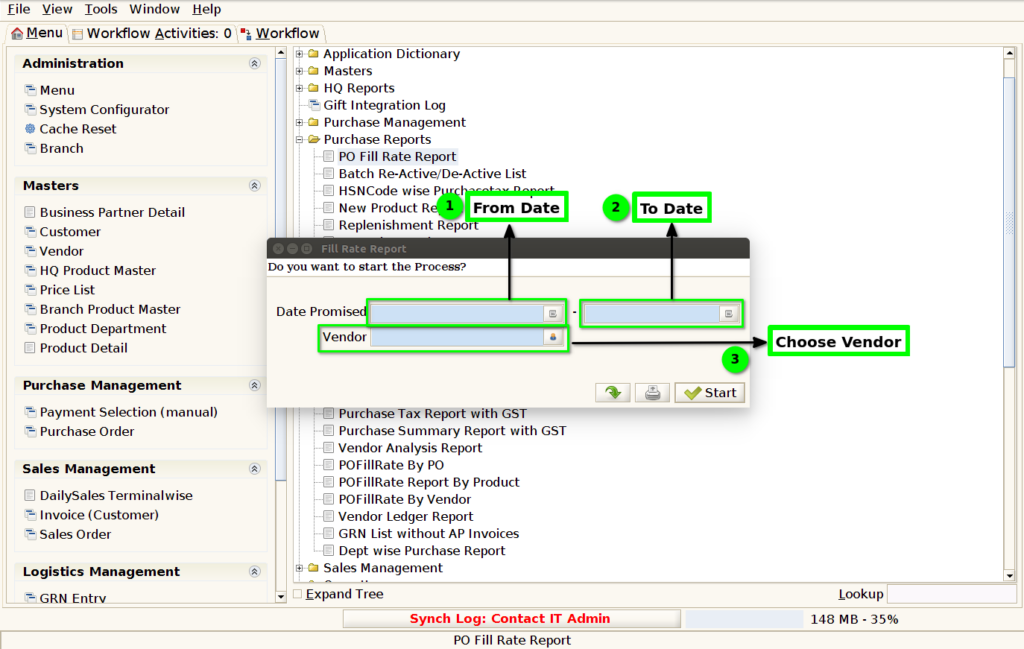

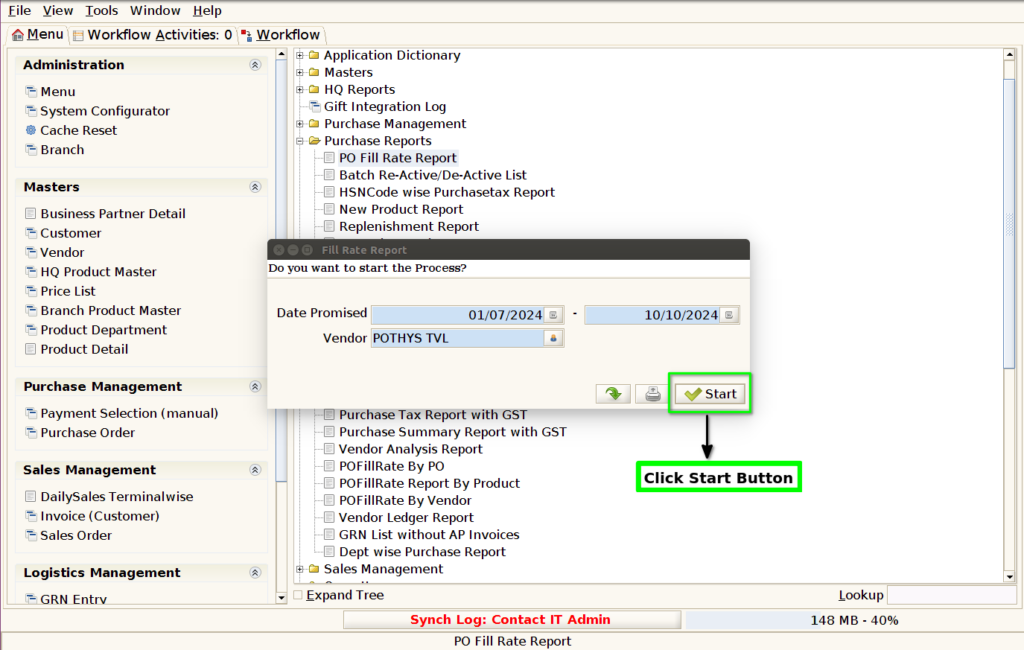

STEP3: Choose Parameter From Date, To Date and Vendor Mandatory

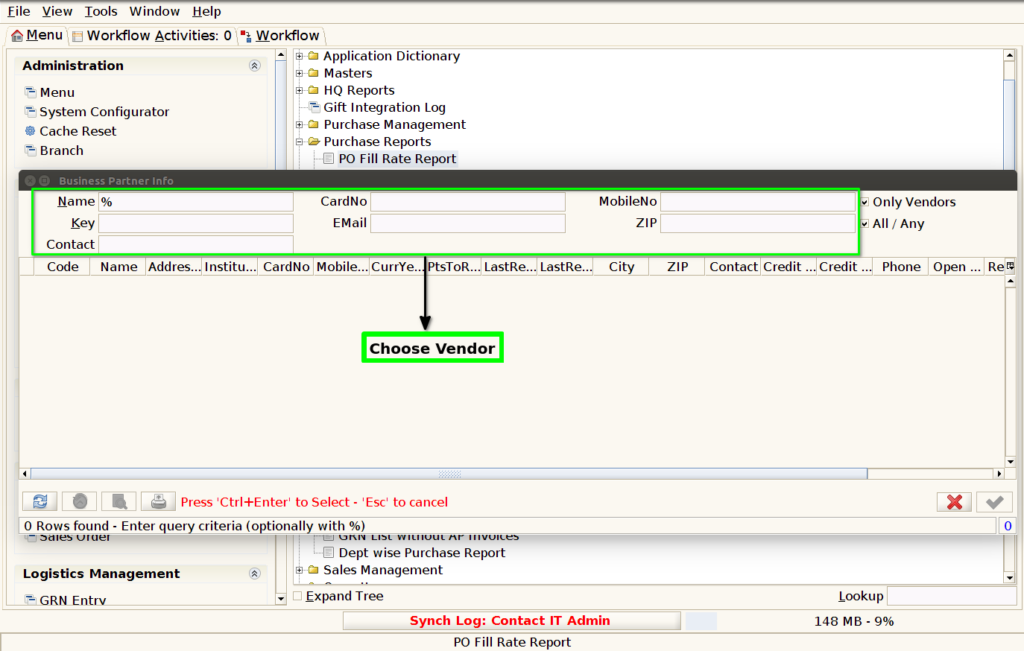

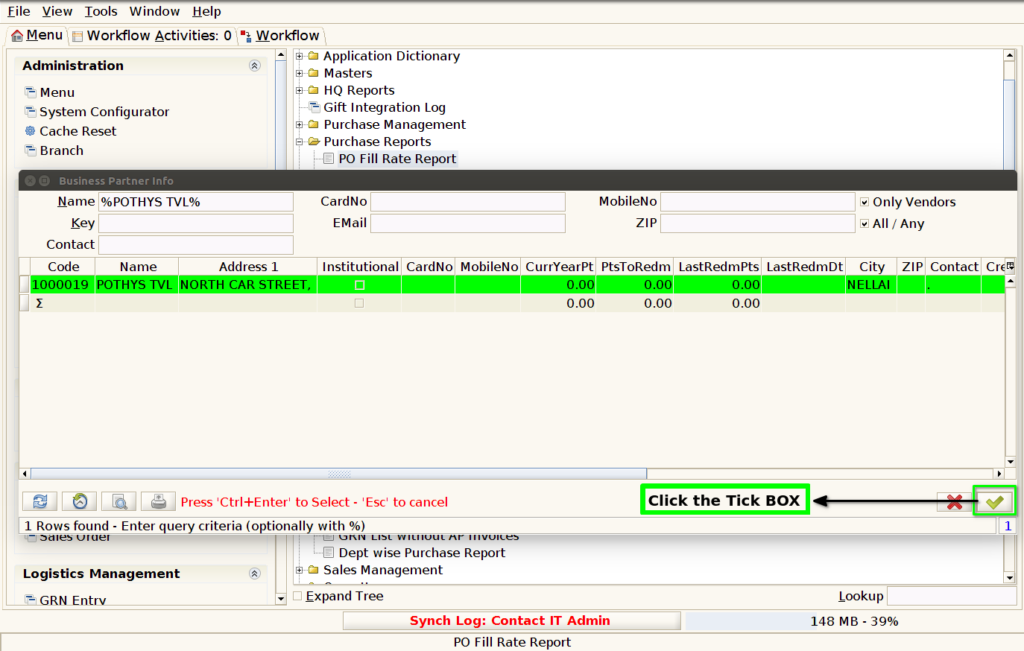

STEP4: Choose Vendor.

STEP5: Click the Tick Box.

STEP6: Click Start Button Start the Process.

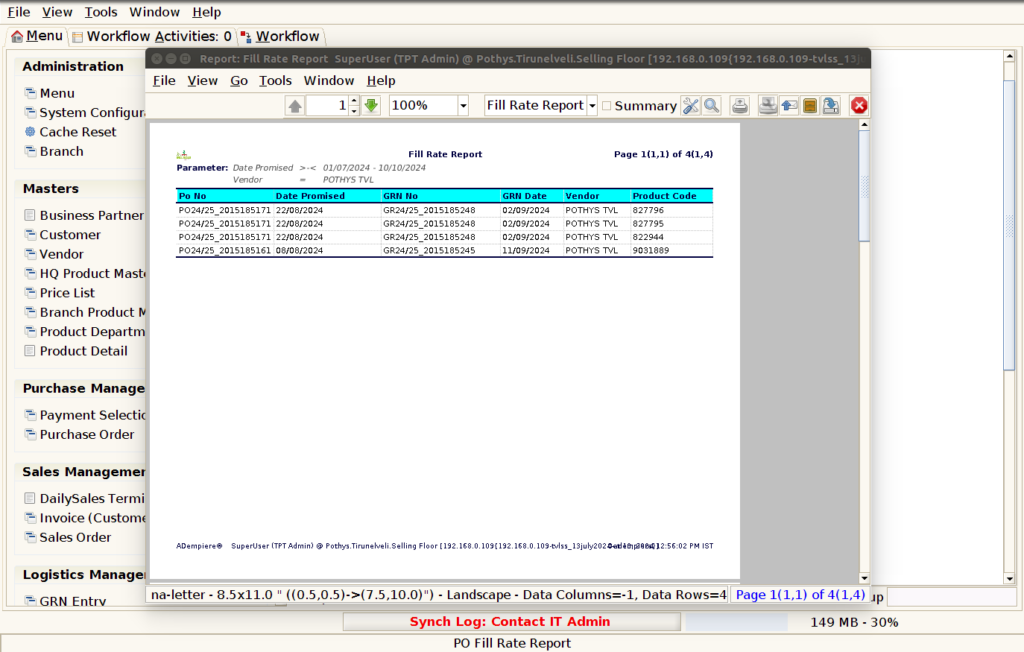

STEP7: To show the report based on the given data.

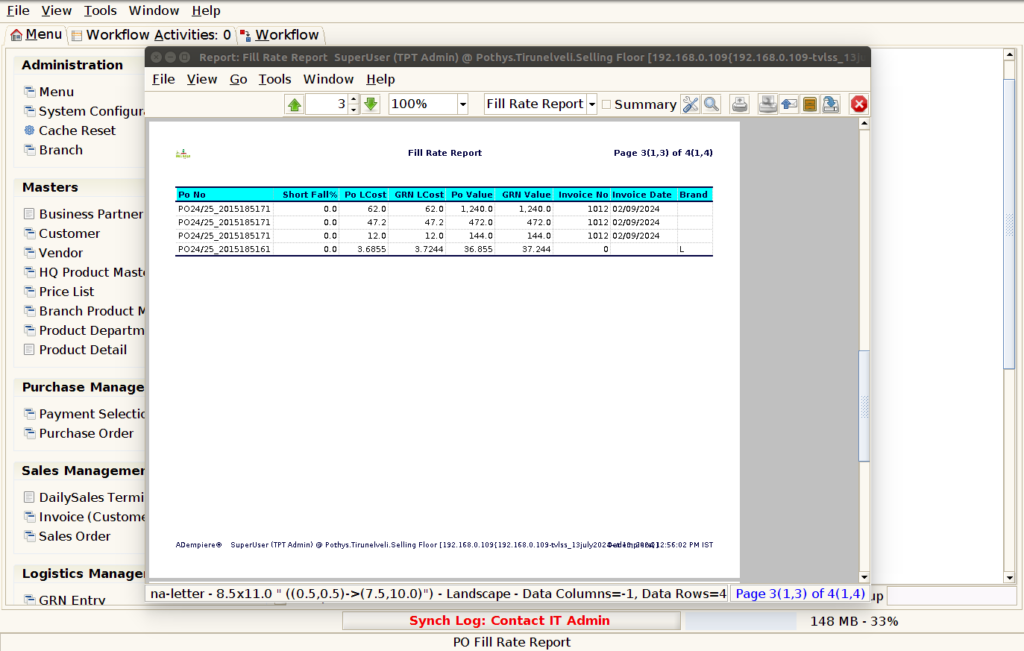

STEP7: PO number – in a PO (Purchase Order) report refers to the unique identifier assigned to a specific purchase order. It serves as a reference number that helps both the buyer and seller track and manage the transaction throughout the procurement process.

Date promised – in a purchase report refers to the specific date on which the seller has agreed to deliver the goods or services to the buyer. This date is typically mentioned in purchase orders or contracts and serves as a commitment by the seller to fulfill the order by that time.

GRN number – is a unique reference number assigned to each Goods Receipt Note for tracking and record-keeping purposes.GRN stands for Goods Receipt Note. It is a document used in inventory and supply chain management to confirm the receipt of goods.

GRN Date – refers to the Goods Receipt Note Date. The GRN is a document that confirms the receipt of goods from a supplier. When goods are delivered to a company, a GRN is generated, and it serves as a record of the quantity and condition of the items received.

Vendor – is a person or company that sells goods or services to another entity. In business terms, a vendor is often a supplier who provides products or services to a customer, often as part of a supply chain.

Product code – is a unique identifier assigned to a specific product or item. It is typically used for tracking and managing inventory, orders, and purchasing transactions. The product code helps differentiate between similar items and allows for efficient record-keeping.

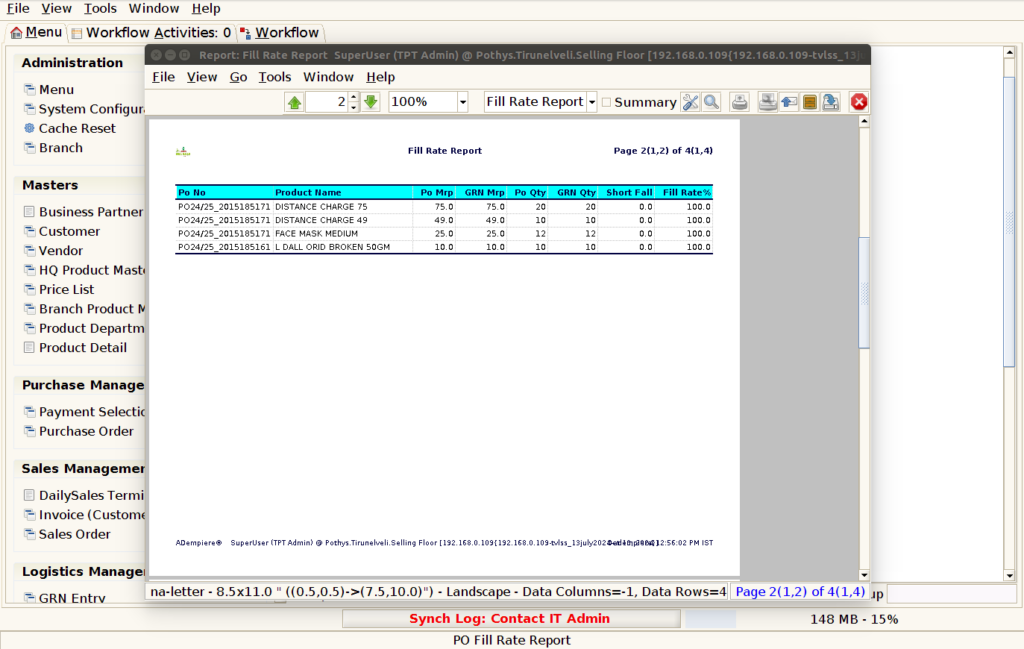

Product Name – typically refers to the specific name or description of the items that were purchased. This column or data point identifies what goods or services were acquired during the purchasing process.

PO MRP – generally refers to the MRP details linked to a purchase order. This can involve – Planned Order Quantities: The quantities of materials or components required as determined by the MRP process, which could trigger the creation of a PO.

GRN MRP -(Material Requirement Planning)MRP is a system or methodology used to plan the procurement and manufacturing of materials. It is used to calculate the materials needed based on demand forecasts and inventory levels.

PO Qty (Purchase Order Quantity) – This refers to the quantity of items that a buyer orders from a supplier or vendor. It is the amount of goods or services the buyer expects to receive. – The PO quantity is a key figure in the ordering process and is used to track the purchase requirements of a business.

GRN Qty (Goods Receipt Note Quantity)– This refers to the quantity of goods actually received by the buyer, as recorded in the Goods Receipt Note (GRN).The GRN is a document created when goods are received from the supplier.

Shortfall – refers to a situation where the actual quantity or value of purchased goods or materials is less than what was expected or required, often indicated in a report comparing fore casted or planned purchases against actual purchases.

Fill rate%– refers to the percentage of customer orders or demand that is successfully fulfilled with the available stock or products during a given period. It is a key metric for supply chain and inventory management, indicating how well a company is able to meet customer orders without back ordering or stock outs.

Shortfall % – refers to the percentage difference between the quantity of goods that were expected or ordered versus the quantity that was actually received.

PO Landed Cost (Purchase Order Landed Cost)– This refers to the total cost of a product or goods after factoring in all expenses associated with purchasing, shipping, customs, and delivery up to the point the product arrives at the company’s location.

GRN Landed Cost (Goods Receipt Note Landed Cost)– A GRN (Goods Receipt Note) is a document created when goods are received by a company. The GRN Landed Cost refers to the total cost of the goods that are recorded in the GRN, including all additional costs that were added to the goods after they were ordered but before they were received.

PO value – refers to the total monetary amount indicated in a Purchase Order (PO). A PO is a formal document issued by a buyer to a supplier, specifying the types, quantities, and agreed prices for products or services.

GRN value – refers to the total monetary value recorded in a Goods Receipt Note (GRN), which is a document created by a company when goods are received from a supplier.

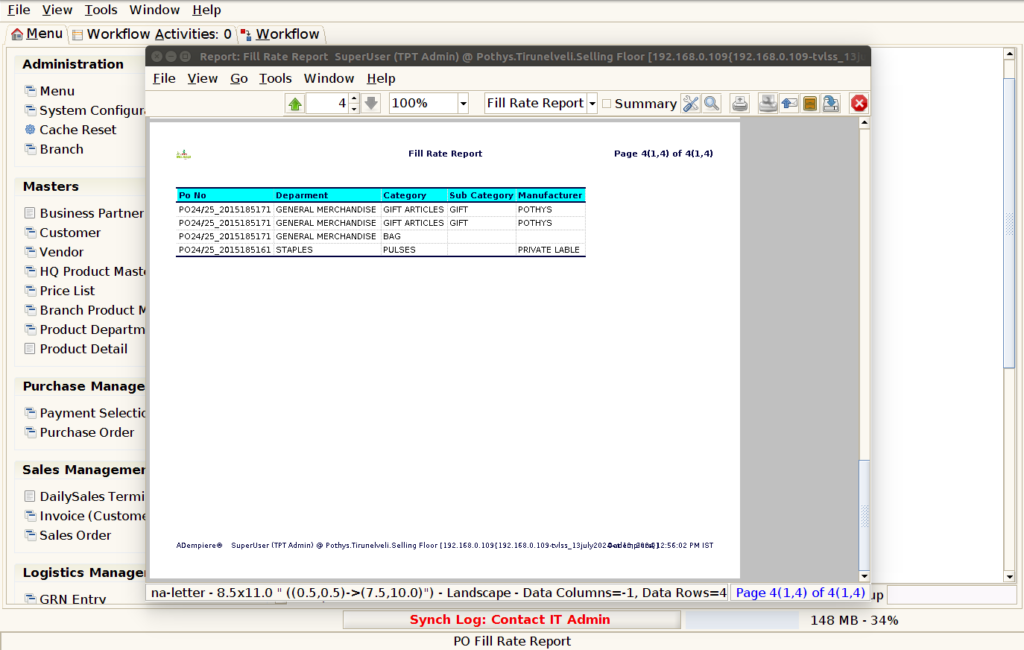

Brand– A brand is created through design, packaging, and advertising elements that distinguish the product from its competitors.

Category -is a way for a business to group similar items together for customers to find them, whether in a store or on a website.

Department -for each product and that department controls all activities related to the product including development, production, marketing, sales, and distribution.

Invoice number – is a unique identifier assigned to each invoice issued by a seller or service provider. It is typically a sequential number that helps in tracking and managing invoices for accounting, auditing, and reference purposes.

Manufacturer – refers to the company or entity that produces or makes the products being purchased. This term is important in tracking the source of the products, as it helps identify who is responsible for their creation.

Sub-category – typically refers to a more detailed classification within a broader category of purchased items or services. It helps break down the main categories into smaller, more specific groups for better tracking, analysis, and reporting.

Invoice date – is the date when the invoice is issued by the seller or service provider. This date marks the official record of the transaction and can be used for tracking payment terms, deadlines, and financial reporting. It is important because it determines when the payment is due (e.g., 30 days after the invoice date) and may impact tax or financial reporting periods.

Training Videos

FAQ

SOP