TO CREATE A PRODUCT BATCH FILTER REPORT

A Product Batch Filter Report is typically used in industries where products are manufactured in batches (such as pharmaceuticals, food and beverage, or chemicals). It allows users to filter and analyze products based on their batch information. The batch refers to a specific quantity of product that is produced under similar conditions and within a defined time frame. This kind of report is valuable for tracking, quality control, and ensuring consistency across product batches.

User Access

Who Can Access

- Pothys admin

- Back Office

- Purchase Manager

- Manager

What User Can Do

- View Reports

- Product batch filter report

Pre-Requisite Activities

- No of Batches

- HSN Code

- Product

- Department

- Category

- Brand

- Sub category.

Business Rules

- Batch Identification and Filtering – Batch Number-The report must allow filtering based on specific batch numbers (e.g., Batch ID or Batch Code).

- Date Range-The report should allow filtering by the batch’s production or release date, with a start and end date field for customizable range selection.

- Product Type-Users should be able to filter the report based on the product or product category associated with the batch.

- Status- Filter by batch status (e.g., In-Production, Completed, Shipped, Cancelled, On-Hold). This helps identify batches in specific phases.

- Location-The report must allow filtering by the production or storage location of the batch (e.g., manufacturing plant, warehouse).

- Quality Control Status-Filter based on whether the batch passed or failed quality control (QC) checks.

- Batch Attributes and Information – Quantity Produced-The report must show the total quantity produced or processed in each batch.

- Lot Number-If applicable, the report should include the lot number(s) associated with each batch, particularly in industries like pharmaceuticals or food production.

- Expiration Date-Display the expiration date for products in the batch, if applicable, and allow filtering by date.

- Data Validity -Incomplete Data- The report must flag or exclude batches that have incomplete or missing data (e.g., missing QC results, or incomplete production logs).

User Interface

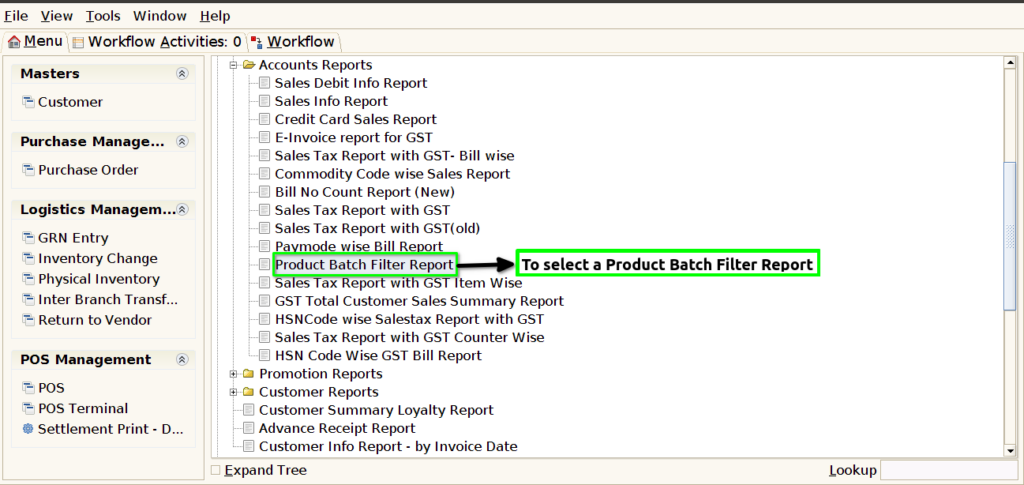

STEP 1: To select a Product Batch Filter Report.

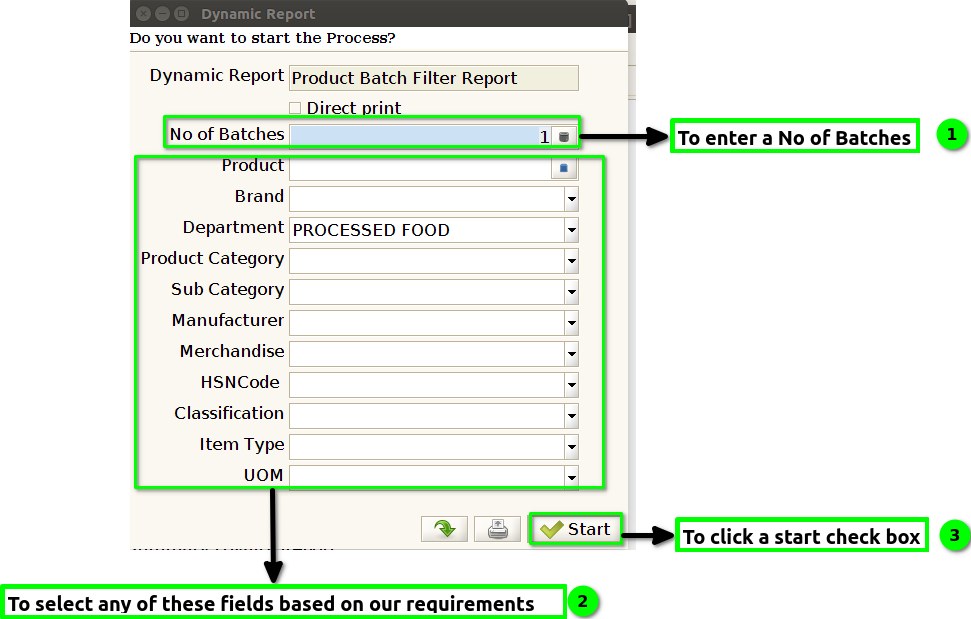

STEP 2: To enter a No of Batches in this field is mandatory.To select any of these fields based on our requirements.To click the start check box and to run the process.

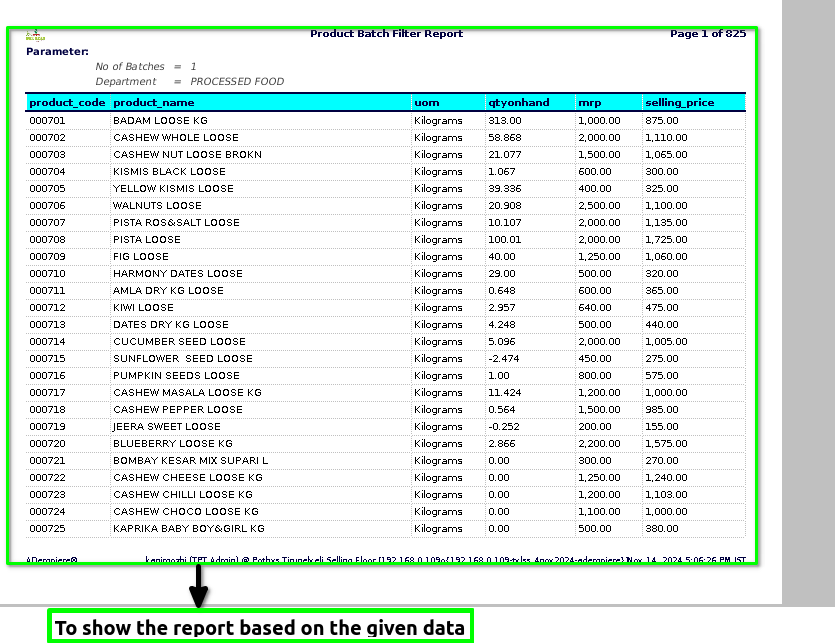

STEP 3: Once to complete the process to show the report based on given data.

STEP 4: Product code-is a unique identifier assigned to a product by its manufacturer or seller. It is used to distinguish the product from others in a catalog or inventory system.

Product name-is the title or label given to a product that differentiates it from other products in the market. It is usually chosen by the manufacturer or brand owner and serves as an identifier for consumers to recognize and distinguish the product.

UOM– stands for Unit of Measure, which refers to the standard quantity used to measure a product or item. It defines how a product is quantified or sold, such as by weight, volume, length, or count. For example, a UOM could be “kilograms” for weight, “liters” for volume, or “pieces” for individual items.

Quantity on hand-refers to the amount of a particular item or product that is physically available in inventory at any given moment.

MRP-stands for Material Requirements Planning. It is a production planning and inventory control system used to manage manufacturing processes.

Selling price -is the amount of money a buyer pays to purchase a product or service from a seller. It is the final price at which an item or service is offered for sale to customers, and it typically includes the costs of production, distribution, and any markup for profit.

Training Videos

FAQ

SOP